Update 20.03.2013

Probably every computer enthusiast has long been visited by the thought of assembling a “system unit” with his own hands.

Installing the OS and other application software has long been a passed stage.

But to assemble a completely ready-to-work computer from components is not so simple as it seems at first glance.

This article will be a detailed instruction manual for assembling a computer, or rather a system unit, from separately selected components.

How to choose components for the system unit, we read in our articles:

- .

- .

- ?

- .

- .

- .

The article describes the assembly of a budget system unit.

It is clear that with the release of new components, this system is no longer relevant.

But we are not describing a specific set for a gaming / media computer, but the principle itself, the method and sequence of assembling the system unit. Which is not very different from other systems.

Let's start in order:

1. So we get the case.

We have chosen and purchased the case CoolerMaster Elite 332

.

The case is made of rather thick metal, has convenient clamps for screwless installation of equipment.

A high-quality power supply is installed in the case, with a power of 460W or 500W (optionally selected using), which is able to provide a medium-gaming system and has all the necessary (for us) connectors.

The package also includes all the necessary mounting screws, motherboard holders and even a ferrite ring, which is used to eliminate electrostatic interference from consumers connected to the front panel.

2. Then we take the motherboard.

Article

The choice fell on ASUS P8P67LE

- This is an excellent motherboard based on the new P67 chipset and with CrossFireX support.

The package includes 1 ATA cable, 2 SATA 3Gb/s cables and 1 SATA 6 Gb/s cable (!).

in appearance it differs from ordinary sata cables

We prepare the motherboard for installing the processor. We open the latch and remove the protective insert of the mat socket. boards, shipping film from the chipset heatsink and a sticker with PCI connectors

3. The next component will be our processor.

Article

Chosen and purchased Intel Core i3-2120

– 32nm dual-core processor, clocked at 3.3GHz per core, and supporting HT (Intel® Hyper-Threading) technology.

Due to which each processor core is capable of computing in two threads.

It turns out 2 cores / 4 threads. Windows 7 sees this processor as a quad-core processor.

The BOX delivery set includes the processor itself and the cooler, with thermal paste applied

We take out the processor and just put it in the motherboard socket. We control the coincidence of all "keys" and pointers.

In principle, it will not work to put the processor in another way (they will not give the keys), but it is better to check once again.

Then we close the frame and fix the latch - the processor is installed.

4. Next, take the cooler (radiator + fan) and install it in the motherboard holes.

At the same time, we check that all four cooler latches are closed (turned all the way in the direction opposite to the drawn arrow).

In turn, gently, crosswise, press the latches to the motherboard until they are fully fixed. Mat. it is better to take the board in your hands and, pressing it, hold it on the reverse side.

Then be sure to check if all the latches are fully latched. If not, then press gently.

Now we connect the fan to the connector cpu_fan motherboard.

5. We take RAM modules.

Article

We have chosen budget slats DDR3

frequency 1333Mhz 2 x 2Gb

but well-known company G.SKILL

.

The slats are taken from the same batch, for correct operation in two-channel mode.

It was possible to focus on a KIT-set, but we had a too limited budget.

We decided to stick with these.

We completed the next two systems with the DDR3 4096Mb CORSAIR (CMZ4GX3M1A1600C9) Vengeance KIT with a frequency of 1600 Mhz

According to the motherboard specification, in order for the memory to work in Duall Chanell, the brackets must be installed in the first (DIMM_A1) and third (DIMM_B1) slots (channel A and B).

We open the latches of the memory slots and put the memory according to the key (jumper) on the memory bar and slot. The memory is installed by pressing both edges evenly until the latches are fully seated and closed. Given that everything is new, the latches can be tight, then you need to help close the latches a little.

As a result, we have something like this

6. We mount the rear bar included in the mat. boards, in the computer case

Now we take the motherboard and “try it on” into the case to find out which holes we need to screw the board holders into. Having decided - we screw it.

Before fixing the motherboard, we lay under it (so as not to interfere) an audio cable coming from the front panel, and connect it to the connector front panel audio connector (AAFP)

.

Different boards have a different location of the front panel audio connector. For more details, see the manual of the motherboard kit or download the manual from the office. manufacturer's website fees.

Then we insert the mat into the back bar. board and fix it with screws to the holders

be sure to pay attention to the screws with the desired thread

Then we connect in series all the control and indication of the front panel of the case (we strictly observe the polarity, the white wires are “minus”, the colored ones are “plus”).

In the installation instructions mat. The board has a detailed description and illustration of how to connect the USB port and front panel control, up to the full pinout. On the boards of different manufacturers, the front panel is connected in different ways. For more details, see the manual of the motherboard kit or download the manual from the office. manufacturer's website fees.

POST speaker

Power and Reset buttons

HDD indicator (red LED) and power indicator

Again, due to a very limited budget, I had to buy a cheaper CoolerMaster fan (but it is undesirable to completely abandon it).

We completed all subsequent systems with a better and more productive model. CoolerMaster SickleFlow 120mm 2000RPM Blue LED

We remove the front panel, in this case it is held on by simple latches, in other cases it can be fastened with screws.

We install an additional fan, and strictly for blowing (with the fan housing inside the computer case)

And connect to the connector cha_fan2 on the motherboard

While the front panel is removed, we are preparing a place to install our DVD drive.

Close the front panel.

We lay the wires coming from the front panel and fix them with vinyl clamps

8. The next step is to install the HDD into the computer case.

Article and/or .

Due to the limited budget, we chose a production hard drive WD volume in 500Gb with 16 Mb cache and interface SATA3 6Gb/s .

We completed subsequent systems with a fast, single-pancake, quiet hard drive Seagate Barracuda 7200.14 1TB 7200rpm 64MB ST1000DM003

with 64 Mb buffer (cache).

Our motherboard just has 2 SATA3 connectors, which are marked in white and signed as SATA 6G

We insert the hard drive into the case so that it is blown by the front fan on both sides, and fix it with mounting latches.

In other cases, fixing is done with screws.

3DNews has a large and diverse audience. The resource is visited by both seasoned enthusiasts who have assembled far from one PC, and readers who are just starting to delve into all the intricacies of computer technology. The test lab elegantly overclocks them to serious frequencies, to study the durability of drives, in modern games and to purchase unusual hardware abroad, but at the same time, it does not forget about inexperienced users. So the heading "" appeared, which offers a variety of configurations of system units. After reading the comments and personal communication with the readers of the site, it became clear to me that it was time to tell in detail and show newcomers how to assemble the components proposed in the article into a single whole. This is what this article is about.

⇡ Selection and compatibility of components

Sometimes it’s harder to decide on a set of components that will make up your PC than to assemble a system unit at home with your own hands. On sale you can find a huge number of processors, motherboards and video cards. You can argue for a long time about which brand is preferable, as well as discussing whose graphics are faster - the main thing is that when you finalize the configuration, all hardware is fully compatible with each other. By the way, it is precisely such systems that I offer in "". Subject to this rule, the assembly of the system unit is not much different from the game of constructor, in which all the parts fit together. Component sizes, mounting hole parameters and connectors - all computer elements are strictly regulated, and therefore, for example, it cannot be that DDR3 RAM suddenly works on a motherboard with DIMM slots designed to install exclusively DDR4 modules. You simply cannot install them in the appropriate slots.

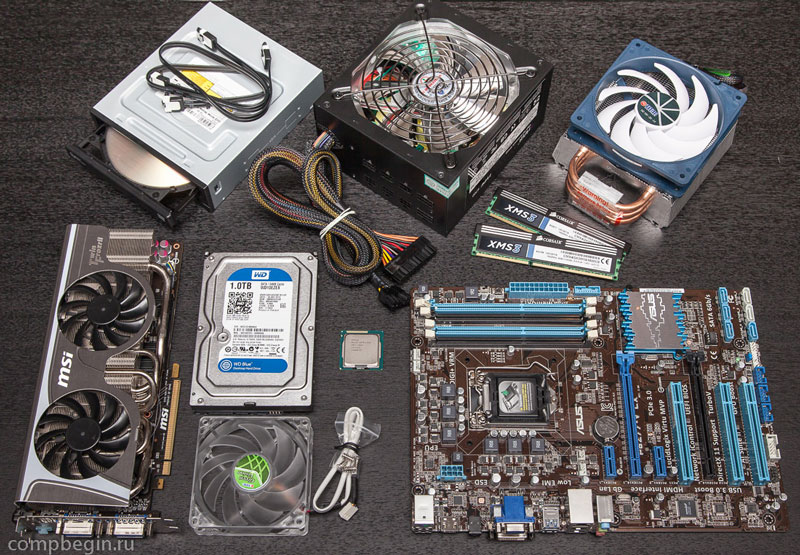

For the full functioning of the system unit, you must purchase the following devices: motherboard, central processor, cooler, RAM, hard drive or solid state drive, video card (if the CPU or motherboard does not have an integrated graphics core), power supply and case. Additional components include an optical drive, as well as all kinds of discrete devices: network and sound cards, additional cooling.

The motherboard is the backbone of any computer. It depends on it which processors will be used, how many RAM modules, video cards and drives can be installed. Motherboard dimensions also play an important role in case selection. At the moment, among motherboards, solutions of the form factors E-ATX (305 × 330 mm), ATX (305 × 244, 305 × 225 or 305 × 199 mm), mATX (244 × 244, 244 × 225 or 191 × 188 mm) and mini-ITX (170 × 170 mm), although there are much more standard sizes of such devices. The form factor is always listed in the chassis specifications.

The “home” for components itself is also divided into types depending on the size and shape. As a rule, the larger the computer case, the more productive hardware we can install in it, while ensuring high-quality cooling of all system components. Dependence, however, is non-linear - practice shows that it is quite possible to assemble a powerful gaming PC in compact cases with a volume of 7-10 liters. You just have to carefully select all the components first.

Among PC cases, four types of models are most popular: Midi-Tower (examples - and), Full Tower (), Mini-Tower () and Slim Desktop (). Naturally, the smaller the device, the fewer seats it has for installing discrete video cards, drives, and case fans. For example, the Node 202 with a capacity of 10 liters can only install 2.5-inch hard drives and SSDs. A conscientious manufacturer indicates all these features in the technical characteristics of the device.

When choosing components, pay attention to other limitations that any computer case has:

- maximum height of the CPU cooler;

- maximum length of the video card;

- maximum length of the power supply.

Before buying equipment, be sure to make sure that all devices are compatible with each other, do not conflict and fit exactly in the computer case. The simplest logical chain that will not allow you to purchase components that do not match each other is as follows:

- We determine the model of the central processor.

- We select a motherboard with a suitable socket for this CPU.

- We study the list of compatible motherboard hardware on the official website and select a set of RAM.

- Choose drives that are compatible with the motherboard.

- We select a video card, power supply, processor cooling and a case that will fit all the components.

Again, the above sequence is by no means an axiom. Since building a PC is always a creative process, the sequence of choosing hardware can change. For example, you liked a certain case and want to assemble your dream system only in it. Or do you already have some components on hand, and you need to buy everything else.

If the system unit will use an unattended water cooling system for a processor or video card, then it is additionally necessary to find out the sizes of supported radiators, as well as the places where they can be installed. It is obvious that the seats for installing the SVO coincide with the places where the fans are attached. Single-section radiators are usually installed on the rear wall, two-section and three-section - on the top and / or front.

To write this material, based on the above sequence for selecting components, I used the following set of devices:

- AMD Ryzen 7 1700 CPU, socket AM4, 3.0 (3.7) GHz;

- MSI X370 GAMING PRO CARBON motherboard, socket AM4, X370 chipset;

- RAM Kingston HyperX Fury (HX426C16FR2K4 / 32), 4 × 8 GB, DDR4-2666;

- solid state drive;

- video card;

- power supply Cooler Master MasterWatt, 500 W;

- case Cooler Master MasterBox 5 MSI Edition;

- processor cooling Cooler Master MasterLiquid 120.

As you can see, in preparing this material, the most common form factors are used - ATX for the motherboard and Midi-Tower for the case. Similar options are offered in the "Computer of the Month" - because this size is the most versatile and most popular. True, I cannot say that the assembly process in Mini-Tower and Slim Desktop cases is fundamentally different. It's just that the requirements for the selection of iron compatible with each other turn out to be much higher.

In addition, I note that when selecting devices, all modern trends are taken into account. The main drive is the Kingston HyperX Predator model with a PCI Express interface. And the choice in favor of Cooler Master MasterBox 5 MSI Edition was made because of the possibility of installing a power supply unit in the lower part of the chassis, as well as the presence of a mount for drives on the barrier wall. Plus, maintenance-free liquid cooling systems are very popular. Cooler Master MasterLiquid 120 is a bright representative of one-section dropsies that are ready to work out of the box. The remaining components are selected in such a way that in the end we get a productive system unit for work and entertainment. The optical drive has not been used. In my opinion, in 2017 there is no need for it, and the Cooler Master MasterBox 5 MSI Edition (as well as many other new cases of this format) lacks seats for installing devices in 5.25-inch bays.

To assemble the system unit, you will definitely need two Phillips screwdrivers with different slot diameters, nylon ties and wire cutters. Pliers may come in handy - in cheap cases, threads are cut by eye, as well as double-sided adhesive tape, degreasing liquid and cotton swabs. In order not to scratch the case and not damage the motherboard, I put all the components on a rubber mat. An anti-static wrist strap or gloves are also useful for beginners, but, to be honest, more to give self-confidence. Since assembling a PC includes connecting small connectors to the motherboard, you definitely cannot do without good lighting or a flashlight at hand.

⇡ Step #1. Installing the processor and RAM

The motherboard user manual always contains a description of the installation of all major components and connectors. Beginners, keep this book with you. The sequence of steps for assembling the system unit may vary depending on the type of components. For example, sometimes it is better to install a processor cooler immediately, and sometimes - in the penultimate or last place. Even before fixing the motherboard in the case, you must install the CPU and RAM in the appropriate slots.

You probably know that AMD and Intel processors are structurally very different from each other. So, for AMD chips, protruding contacts, called “legs” by the ironworkers, are located directly on the textolite substrate. But Intel chips do not have such elements - for these CPUs, the contacts are placed directly in the motherboard socket.

AMD chips are installed very simply: raise the lever, put the processor on a plastic substrate, lower the lever.

As for Intel solutions for LGA115X platforms, a similar technique is used here: together with the lever, we raise the clamping frame, install the processor, lower the lever and the clamping frame.

In the case of the Intel LGA2011 and LGA2011-v3 platforms, two levers must be released from the locking slots to raise the clamping frame.

|

|

|

Please note that all CPUs and motherboards are equipped with pointers and so-called foolproofing. In principle, you will not be able to install the chip into the socket in any other way, so NEVER use force when assembling a computer. All elements in the system unit are equipped with protection against incorrect connection. In addition to the CPU, you will not be able to connect power supply cables, case connectors, fans, discrete devices, drives and RAM in any other way. More precisely, you can, but this will require maximum effort. I think it's not worth talking about the consequences of improper installation of PC components.

After the CPU, I install RAM into the DIMM slots, usually located on the right side of the CPU. MSI X370 GAMING PRO CARBON supports DDR4 RAM, four ports are soldered on the printed circuit board at once. In some motherboards, there may be only two of them (most often these are either the cheapest devices, or mini-ITX form factor solutions, or), in models for the LGA2011 and LGA2011-v3 platforms, eight. Usually on PCB all DIMM slots are marked.

Most modern AMD and Intel processors have dual-channel RAM controllers. Therefore, motherboards use either two or four DIMM slots. Therefore, the installation of either two or four RAM modules is considered optimal. In the first case, RAM is installed through one connector. Some motherboards have special pointers. For example, in the MSI X370 GAMING PRO CARBON, modules are installed in the DIMMA2 and DIMMB2 slots - in this case, the RAM will work in dual-channel mode. In other motherboards, there are inscriptions like - in such cases, to ensure the operation of the dual-channel mode, the modules must be installed in the DDR4_A1 / DDR4_B1, DIMM_A1 / DIMM_B1 and DDR4_1 / DDR4_2 slots, respectively.

"Fool-proof" in RAM

I have already said that it will not work to insert the RAM incorrectly, since a jumper is used in the design of the DIMM connectors. It is also used to prevent the user from "squeezing" modules of another standard into a motherboard that supports DDR4.

RAM boards are fixed using latches located along the edges of the DIMM slots. On some motherboards, these latches are located on only one side of the connectors. This is done so that the user can freely change RAM modules without removing, for example, a video card.

After installing the CPU and RAM, you can immediately install a CPU cooler, but only if its design uses a small heatsink. The use of an overall cooling system will make it difficult to install the motherboard, as well as the subsequent connection of wires. The photo above shows examples of installing boxed coolers - the so-called COs that are sold together with processors. Coolers for AMD AM3+ and FM2+ platforms are attached using plastic "ears" - a special metal bracket with lugs clings to them. Boxed cooling for Ryzen chips is installed differently, here you have to work with a screwdriver: first remove the plastic mount, and then screw the heatsink to the backplate. The cooler for Intel processors is attached using plastic clips: install the heatsink on the CPU and press the latch until you hear a characteristic click. In general, in the case of installing boxed cooling systems, even beginners should not have problems.

Some coolers already have thermal paste on the soleplate - its use significantly increases the efficiency of heat removal from the CPU. In any case, thermal paste is always included with the CPU cooler. For example, Cooler Master MasterLiquid 120 came with a small tube, which, nevertheless, should be enough for 3-4 times. Please remember to remove the protective film before installing the cooling system, if any, on the base of the device. The process of applying thermal paste is described in paragraph number five.

But the installation of other coolers is carried out on an individual basis, since each manufacturer uses a fixing kit of his own design. Therefore, immediately take out the instructions from the packaging from the CO. Most devices are equipped with universal mounting mechanisms that are suitable for both AMD and Intel processors. True, the mating part of the mount, which must be pre-fixed on the board, is different for different platforms. The list of supported equipment, as well as the dimensions of the cooler, are always indicated in the technical specifications. And yet, there are enough models on sale that are compatible with only one specific platform.

Once again: if the device is large or, as in my case, a maintenance-free liquid cooling system is used, then at the first stage it is enough to fix the back plate and frames on the board, which will hold the cooler radiator. We will install the radiator itself in the penultimate turn, after all the cables are connected to the motherboard. Yes, in cases of the Cooler Master MasterBox 5 MSI Edition level, the barrier wall has a window for accessing the cooler's backplate, but it is far from always convenient to use it.

If we talk about air processor coolers, then the tower-type coolers are considered the most popular. Depending on the platform used and on the specific model, the CO radiator can be installed in two positions. In the first case, the cooler fan will blow air through the back wall of the case, in the second case, through the top. The correct installation option determines the shape of the enclosure used. So, in the case of models of Full-, Midi- and Mini-Tower formats, it is better to use the first option. It is important that the CO used does not overlap the expansion slots, and also does not rest against the cooling elements of the motherboard power subsystem. For example, MSI X370 GAMING PRO CARBON does not conflict with even the largest cooling towers. Also, a wide CPU cooler can interfere with the installation of RAM modules with tall heatsinks. Therefore, it is better to use compact RAM kits, such as the Kingston HyperX Fury for example, or make 100% sure that CPU cooling and memory will not conflict with each other.

Our build uses the maintenance-free Cooler Master MasterLiquid 120 liquid cooling system, so it will be installed last but one (step #5).

Cooler and case fans are connected to the motherboard using 3- and 4-pin connectors. The MSI X370 GAMING PRO CARBON has six such elements soldered at once, which is very convenient. The number of such ports is not regulated in any way, but at least two connectors must be present on the board: for connecting a CPU cooler fan and for a system (case) impeller. All connectors are marked accordingly: CPU_FAN, SYS_FAN (or CHA_FAN). Sometimes a 4-pin connector designed for a processor cooler is highlighted in a different color (most often white). And in the boards of the middle and high price ranges, you can find the PUMP_FAN connector. It is designed to connect the rotor of a water cooling pump, but at the same time it is suitable for any other fans. It's just that a larger current is transmitted through this port.

The connector with three pins does not allow you to adjust the speed of the fan connected to it. But the 4-pin port has such an opportunity, and modern motherboards can control the speed of the “turntables” both with pulse-width modulation (fans with four pins) and without it (fans with three pins).

With a shortage of connectors for connecting case fans, all kinds of adapters will help. This can be an ordinary splitter that allows you to connect several impellers to one 3- or 4-pin port at once. Or a cable connected to the MOLEX or SATA connector. And there are devices such as, although their popularity has never been high. However, they are initially equipped with simple (most often three-position) controllers that control the fan speed by lowering the voltage from 12 to 7 or 5 V.

In the case of our PC, there is no need for additional adapters and splitters, since only two CBO fans and one case impeller need to be connected to the motherboard.

⇡ Step #2. Installing the Motherboard and Connecting the Case Connectors

Now that the CPU and RAM are connected to the motherboard, it's time to start working on the case.

For a long time, in tower cases, the power supply is installed mainly from below. This was done both for aesthetic reasons (it is more convenient and easier to lay wires), and for the sake of increasing the cooling efficiency, primarily of the PSU itself. However, on sale there are models of cases with other options for installing a power supply unit.

Seats for installing the power supply, 2.5- and 3.5-inch drives

The Cooler Master MasterBox 5 MSI Edition is designed with a small sled cage that holds two 3.5-inch hard drives. More compact 2.5-inch drives are mounted on a barrier wall.

Installing the motherboard begins with securing the I/O panel blank in the rectangular hole provided for this purpose. You won't have any difficulties. The plug is always included with the motherboard.

Mounting accessories are always supplied with the housing. Along with the Cooler Master MasterBox 5 MSI Edition, I found three types of screws, as well as plastic clips for installing additional fans. Other housings may have more mounting options. On some models, the standoff screws needed to install the motherboard are already screwed into the corresponding threaded holes on the barrier wall. In the case of Cooler Master MasterBox 5 MSI Edition, you will have to do this procedure yourself.

So, the case supports the installation of mini-ITX, mATX, ATX and even E-ATX form factor motherboards. There are symbols on the wall (a similar memo is used in many models). Since the assembly uses an ATX form factor board, it is necessary to screw all eight stand screws into the threaded holes marked with the letter "A". However, not all motherboards related to this size correspond to the length and width parameters of 305 × 244 mm. For example, the MSI X370 GAMING PRO CARBON is already 19 mm, so it cannot be fixed in the case along the right edge. Therefore, when connecting wires from the power supply or mounting memory modules in DIMM slots, the PCB will sag. Install these items carefully in such cases.

After the motherboard is fixed, I personally immediately connect the controls and connectors of the front panel of the case. On the front wall of the Cooler Master MasterBox 5 MSI Edition, two USB 3.0 A-type ports, two 3.5 mm mini-jacks for headphones and a microphone, as well as system power and forced reboot keys are displayed. Difficulties can arise only when connecting controls - this is a bundle of wires with Power LED- and Power LED + connectors (transfer information to the computer status indicator), Power SW (responsible for the operation of the power key), HDD LED- and HDD LED + (transmit information to the drive activity indicator ), as well as Reset SW (responsible for the operation of the forced reboot button). Some elements may not be on the “face” of the case, since not all devices are equipped, for example, with a Reset key or LED indicators. However, in all cases, these connectors are connected in a certain sequence, as shown in the table below. It's just that motherboard manufacturers use their own designations for essentially the same pad: JFP1 in MSI motherboards; PANEL at ASUS; PANEL1 on ASRock and F_PANEL on GIGABYTE.

| Power LED+ | Power LED- | Power SW | Power SW |

| HDD LED+ | HDD LED- | Reset SW | Reset SW |

In addition, among the internal connectors on the motherboard, there may be pads for connecting USB 3.1 and USB 2.0 ports, RGB strips, a TPM module, FP audio, and a speaker.

In the first part of a detailed manual for assembling a computer with our own hands, we will talk about installing a processor on the motherboard, installing its cooling system, and installing RAM.

Introduction

In recent years, the computer industry is experiencing a real boom in demand in the mobile PC segment. Smartphones, laptops, ultrabooks, all-in-ones and of course tablets that have flooded the market are increasingly replacing classic desktop computers from our lives. All sorts of reports from various analytical agencies testify to this trend.

But even ten years ago, everything was completely different. Sales of system units and components for them were the main source of income for many computer companies, and low-power and expensive laptops were practically not regarded by users as an alternative to a stationary home PC.

It was this time that can be called the heyday of "self-assembly", when the vast majority of sold system units were assembled not at company factories or factories, but in small pavilions of computer markets, by the hands of self-taught sellers. The users themselves did not lag behind them. The most creative and experienced of them preferred to independently assemble the future PC itself at home. And it must be admitted that this approach had many advantages. Components separately, as a rule, cost less than a computer assembly. Moreover, it was possible to choose a suitable iron manufacturer, excluding the possibility of low-quality equipment made by unnamed handicraft Chinese companies (it was called “noname”) in your desktop.

To date, self-assembly of the system unit is less and less practiced by users. And this is not surprising. As we have already noted, on the one hand, the desktop PC market is now in decline, due to the rapidly increasing popularity of mobile computers. On the other hand, huge competition and the development of iT technologies have made it possible to saturate the market with inexpensive computer devices that make self-collection impractical for the sake of cost savings.

And yet there are still quite a few enthusiasts who prefer not only to independently configure and select components for their future electronic machine, but also to assemble all this with their own hands. Especially it concerns high-performance computers of average and top level. After all, it is this approach that allows you to choose the right balance between the installed devices and their cost, without worrying that, for example, with a powerful processor, you will install a weak video card with a large amount of video memory, which simply will not be used. Also in this case, there are always ample opportunities for the subsequent modernization of the system unit, modding and prompt minor repairs.

Thus, despite the fact that assembling a PC with your own hands is gradually fading into the background, this issue is still relevant. Therefore, we decided to prepare material, or rather even a manual for novice users, where it will be popularly described in detail how to assemble a system unit on your own at home.

Before Assembly

Before starting the assembly, let's get acquainted with the components that our future computer will consist of. Here it is worth mentioning right away that in no case do we urge you to assemble a PC of the same configuration and from the same parts that will participate in this material. All equipment, on the example of which the assembly will be demonstrated, is a purely personal preference of one person and has nothing to do with advertising of certain brands and manufacturers.

So, in our case, solutions from Intel were chosen as the main platform for the future computer, which include a motherboard based on the Z77 chipset with an LGA 1155 connector and a quad-core processor of the Core i5 family. A low-noise tower-type fan was chosen to cool the processor.

The rest of the participants in our assembly were: a pair of 4 GB DDR3 RAM modules, a GeForce GTX 580 video card, a 1 TB hard drive and an additional in-case fan for blowing it, a DVD-RW optical drive, a medium-sized ATX case and a power supply 700 W.

In order to assemble all this into a single whole, we need only one tool - a medium-sized Phillips screwdriver, preferably with a magnetic tip. And of course a pair of straight arms.

Everything is ready to start assembly and now it's time to remember one important detail - static electricity, which in some situations tends to accumulate on our body. All computer components, with the exception of the power supply, are low-voltage equipment and can easily burn out even from the shortest high-voltage discharge. But the banal combing of hair or rubbing against woolen things can lead to the accumulation of a static charge of several thousand volts. So imagine what can happen if you sparse it on some computer part?

To avoid sad consequences, before taking on the components, be sure to touch any metal object, such as a heating pipe or a refrigerator. If your body was electrified, then in this case, the accumulated charge will instantly be discharged. Also, at the time of assembly, it is better not to wear things that can contribute to the accumulation of static electricity.

The assembly itself is desirable to be carried out on a surface that does not conduct electricity (wood, plastic). If the desktop is covered with a cloth tablecloth, then it is better to remove it for a while, since many fabrics tend to accumulate static electricity.

Processor installation

At the first stage of assembly, we will install the processor and RAM into the motherboard, as well as mount the CPU cooling system. Of course, you can first screw the motherboard into the case, and only then do the above steps. But here it is important to know that some processor fans have mounts, some of which are located on the back of the motherboard, which can make it impossible to mount it when the board is already inserted into the case.

Finding the processor socket on the motherboard is very easy. It has a rectangular shape with sides measuring more than 4 cm, so it is quite difficult not to notice it.

One of the main design differences between Intel and AMD processors is the fact that in the first one, contact pads are used to connect to the connector on the motherboard, and in the second - contact legs.

Accordingly, motherboards also have different sockets, which for Intel microprocessors are equipped with soft spring-loaded legs, and for AMD, with many tiny holes. Recall that in our case we are dealing with an Intel processor and an LGA socket.

Before installing the processor, you must open the socket by pressing the metal lever and pulling it to the side.

After releasing from the mount, move the lift lever up, after which the pressure frame will open.

To prevent incorrect installation of the processor in the socket, manufacturers make auxiliary docking cutouts in the design of their cases. Intel has semi-circular notches on the case, while AMD has beveled corners.

After opening the socket, we take the processor and install it into the socket without any effort or pressure, so that the docking cutouts line up.

Now we close the clamping frame by inserting the protrusion located on it with a recess under the limiter, and return the metal lever of the elevator to its original place, thereby pressing the processor to the contacts in the socket.

At this point, the black protective cap on the pressure frame should fly off, after which it can be discarded. On this, the installation of the processor can be considered complete, so let's move on to installing the cooling system.

Mounting the processor cooling system

To date, there are a large number of various cooling systems on the market that use various methods of attaching to the motherboard. Of course, it's hard to tell about all the nuances within the framework of one article, but it's not necessary, because, as a rule, many coolers with unusual mounting systems are supplied with detailed installation instructions.

We will consider the two most common ways of mounting fans, which are used with various nuances in the vast majority of cooling systems.

To install a cooler in the motherboard, there are four holes next to the processor socket.

In most cases, the cooler mount for modern Intel processors contains four legs that are inserted into these very holes and fixed there by pressing them from above. To avoid distortions, it is better to mount crosswise.

Regular fan for processorsIntel

To dismantle fans with such fasteners, it is necessary to turn the head of the leg counterclockwise by 90 degrees, and then pull it up. After removing, rotate all legs to their original position.

Motherboards with sockets for AMD processors are equipped with a special frame for installing a cooling device, to which a standard cooler is attached with two screws. So everything is simple here.

Let's move on to our case. We ditched the original Intel fan and replaced it with a more advanced low noise tower cooler. Its installation on the system board is somewhat different from the standard procedures described above. Here, to increase the stability of the cooler, a special frame is used in its fastening, which is located under the processor socket, to which it is subsequently screwed. It is with its placement that we will begin.

We apply the frame on the back of the motherboard in such a way as to combine all four holes on both parts. Then we insert the screws that come with the kit, and fasten the nuts on them on the other side of the board, to which the frame will be attached, pressing the base of the radiator in the processor cover.

Processor cooling occurs due to the process of heat exchange between its cover and the base of the cooler. Ideally, the lid and base should fit snugly together to maximize heat dissipation efficiency. But in practice, this is very difficult to achieve, since their surfaces are rough. Therefore, in order to increase the contact area, liquid thermal paste is used to fill microvoids, thereby improving heat transfer between the surfaces of devices.

As a rule, in many solutions, including inexpensive and standard coolers, thermal paste is applied to the radiator of the cooling system at the factory. So you just have to properly fix the fan on the motherboard. But in our case, you will have to apply the thermal paste yourself, since the tube with it comes separately.

You should know that thermal paste should be applied in a very thin layer. The principle, the more the better, does not fit here, as this will only harm normal heat transfer. For application, you can use any handy means, for which there is enough imagination. We used an ordinary cotton swab, after moistening its ends a little so that the cotton wool does not peel off.

Squeeze a small amount of thermal paste from the tube onto the processor cover.

Then spread it evenly over the entire area.

Now, everything is ready to install the cooling system. We take the radiator and remove the protective film from its base.

We install the heatsink on the processor and fix it with a special clamping frame and nuts that are screwed onto the screws we prepared earlier. To avoid distortion of the radiator, tighten the nuts crosswise.

Now it remains to connect the fan to the control connector on the motherboard, and then put it on the radiator, after which the installation of the cooling system can be considered complete.

The connector on the motherboard for the CPU cooler, always located next to the CPU socket, has four pins and is called CPU_FAN.

It should be noted that the cooler itself can often have a three-pin connector, which in any case will be compatible with the one on the motherboard. The presence of the fourth contact is not mandatory, since it is responsible for an additional function that makes it possible to use various automatic fan speed control modes, depending on the processor temperature, using the motherboard BIOS.

Regardless of which connector you have on the cooler, to prevent incorrect connection, auxiliary recesses are always placed on it, so it is almost impossible to make a mistake when connecting the fan to the motherboard.

The installation of RAM completes our first stage of the assembly. This is a very simple procedure, as you will soon see for yourself. It's not difficult to find memory slots, as they have an elongated shape, are always located next to the processor socket and are painted in pairs in different colors. By the way, they have already lit up more than once in many previous photographs.

In our case, we have four connectors in black and blue, which makes it possible, if desired, to install four memory sticks, respectively. In general, different models of motherboards may contain 2 (budget models), 4 (standard) or 6 (legacy models) RAM slots. As you can see, in any case, their number is even. The fact is that it is customary to install memory modules in pairs to enable dual-channel mode, which allows you to double the process of data exchange between the "RAM" and the central processor. That is, if you want to have 8 GB of RAM, then you should buy two 4 GB sticks. Of course, you can install a single 8 GB memory chip instead, but in this case, the performance of the computer will be reduced.

It is not in vain that manufacturers paint RAM slots in pairs in different colors. These are the so-called "banks" (bank), each of which has its own color. To enable dual-channel mode, you need to install a couple of memory chips in one bank, and not randomly. For example, in our situation, we fill either both black slots, or blue ones.

Before installing the modules, spread the white locking levers located on the sides of the selected connectors to the sides. Next, with a light pressure, carefully insert the memory bar into the slot.

In this case, it is necessary to combine the notch on the memory module with the jumper in the connector on the motherboard.

After making sure that the bar has entered the slot, fix it by pressing on the corners of the memory from above until a characteristic click. The side locks must then return to their original position.

We do the same with all the other planks.

On this, the first and most important stage of the assembly can be considered completed.

Do not be surprised, but after installing all the above components, you can start the system for the first time and check its performance. After all, most modern processors have an integrated graphics core, and motherboards have integrated connectors for connecting a monitor. Having temporarily connected the power of the processor and the motherboard, it will not be difficult to turn on the assembled system by closing the corresponding contacts on the "motherboard" with any metal object, for example, a screwdriver. Only experienced users should do this trick. Well, if this is your first build, then go straight to the second stage.

The first step is to determine exactly the tasks for which your future system unit will be used. If the purchase of gaming equipment is planned, then special attention should be paid to the video card, and for a graphics workstation, the processor power and the amount of RAM play a fundamental role. The least demanding in terms of performance are office systems. You do not even need to add an external video card, because the built-in one will be enough. The first step is to select a processor. This element affects the overall performance of the entire system and the more cores there are (and the higher their frequency of operation), the faster operations will be performed.

Next, the PC configurator will help you choose the motherboard. It must be compatible with the CPU and support the RAM of the required frequency. Pay attention to the presence of all the necessary slots and connectors, as well as the size of the motherboard itself (ATX, micro ATX, mini ATX, etc.). Usually, any of them already has a built-in network and sound card. The online store builder site will automatically select the appropriate options after you select the processor, and will exclude the ones that are not suitable. The gaming computer must be equipped with an external video card. If you want to regularly play modern games and forget about upgrading your system for a long time, then it's not worth saving. This also applies to the amount of RAM, it will not particularly affect the cost of a PC, but it will significantly affect performance. The amount of information that you can simultaneously store on your computer depends on the size of the hard drive. But to increase the performance of the system, it is recommended to additionally install an SSD drive. It will contain the OS, programs and applications.

For convenient work with external data carriers, the system unit, if desired, is equipped with an optical drive and a card reader. One of the important elements of the system unit is the power supply. Its power should be selected after calculating the total volume of electricity consumption by components. In addition, leave a margin of 100-200 watts for reliable operation under increased loads on the processor and video card. The designer will not let you make a mistake with the choice of power supply, as it will take into account the components you have chosen and provide only suitable cases with power supplies.

The configuration of a powerful gaming computer provides for an additional cooling system, which is selected automatically, depending on the selected processor. It remains to collect everything in the body. It can be quite simple and straightforward if you plan to install the system unit under the table where no one will see it, or it can have neon lights and a window on the side that allows you to observe the operation of the system (gaming options). This is a matter of taste, but keep in mind that the case for a gaming PC must be roomy and have good ventilation so that the components do not overheat at peak loads.

Any difficulties?

For the convenience of customers, it is possible to send the resulting configuration for printing. And if there are difficulties, then you should take the help of our engineer, who will tell you which components are more correct to use in order to obtain optimal technical characteristics.

By choosing to build a computer with us, you get the best prices and service. We guarantee fast, but careful delivery of your system unit.

What is a PC? This is a complex of elements in which everyone has an important responsibility in the operation of all devices.

For example, there are both separate components on sale, from which you can later assemble the device, as well as ready-made machines.

In the second option, you do not need to spend time selecting the necessary elements, checking their compatibility with other parts, as well as the assembly itself.

You get a ready-made block, which you just need to connect to the network and start working.

But, if you have time and patience, then you can use the computer configurator.

If you are an experienced user who understands the nuances and intricacies of PC components, it is easy to assemble a PC from exactly the components that you need, while significantly saving your money.

Here you can compare the price of the finished product with the price of a set of its components, get acquainted with its performance indicators, as well as analyze prices and choose the most appropriate option.

What is a configurator for?

Thus, having decided on the suppliers, you can proceed directly to the configuration.

The site will provide the entire range of products offered. You can see the specifications of the components.

Separately, there will be a column of the online configurator, which will issue a list of the names of components, as well as their brief description.

Thus, you choose exactly those details that interest you, and exclude those that you do not need.

The configurator calculates the amount for a given set of components. You can also purchase the missing items on your PC, improving it in this way.

Advantages and disadvantages of online configurators

Here you can consider the benefits from different angles. Like any medal, there are two sides to it. Let's take a closer look at all the nuances. The first question will be about the warranty.

When we purchase a ready-made system unit, the manufacturers are responsible for all components.

Your task is to take the equipment to the service center in case of breakdown. And then they themselves figure out what is faulty, what is the reason and whether it can be a warranty case.

Thus, you avoid wasting time and nerves.

In the case of self-assembly of the PC, of course, the warranty also applies to the purchase of components.

But in the event of a breakdown, you must determine for yourself what exactly happened and which part failed.

Many simply do not understand that all these gigabytes and cores do not carry performance characteristics, so they face problems directly when buying when they work with equipment.

Outdated elements that have not been used in everyday life for a long time, but carry an additional cost, may also be included.

PC configurators Ulmart and Ironbook

Using an example, we can take a closer look at the Ulmart and Ironbook configurators.

The Ulmart computer configurator includes a selection of:

- price line;

- processor performance;

- processor family;

- the size of the hard disk;

- video card;

- the amount of memory;

- installed OS;

- optical drive;

- the presence of a wired network and a wireless network;

- motherboard;

- case, power supply;

- audio and video systems;

- processor models;

- the presence of a multiformat card reader;

- the amount of video memory;

- performance evaluation;

- graphics core manufacturer.